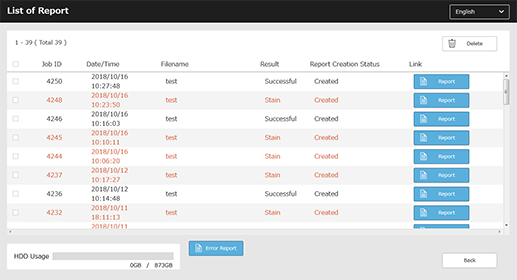

[List of Report]

Overview

Display a list of automatic inspection reports.

Clicking the target automatic inspection report allows you to check its contents.

- The following setting is required to use this function.

- Set the IP address of Auto Inspection Unit UK-301 in [Auto Inspection NIC Setting].

- If an error is detected, the character color is changed.

- If the HDD capacity of Auto Inspection Unit UK-301 reaches 100%, any more automatic inspection reports cannot be created. Select unnecessary automatic inspection reports, and delete them.

- For details about [Auto Inspection NIC Setting], refer to [Auto Inspection NIC Setting].

[List of Report] allows you to check the following items.

Item name | Overview |

|---|---|

[Job ID] | ID of the job for which automatic inspection was performed. |

[Date/Time] | Date and time when the job was output. |

[Filename] | File name of the job for which automatic inspection was performed. |

[Result] | Result of automatic inspection. If a non-standard image occurs, its factor is displayed. |

[Report Creation Status] | Allows you to check the report creation status. If creation is not completed, the detail cannot be viewed in [Report]. |

Specifications

Category | Adjustment / Maintenance | ||

Location | Machine | - | |

Printer driver | - | ||

Application | Web Utilities | ||

Required options | All the following optional devices are required. Intelligent Quality Optimizer IQ-501 Auto Inspection Unit UK-301 Relay Unit RU-702 Video Interface Kit VI-514 Video Interface Kit VI-515 | ||

Required items | - | ||

Setting items | [Japanese] / [English] | Selects the language to display. Select this item from the menu list that is displayed by clicking Advanced Options. | |

[Delete] | Deletes the report of the job of which the check box is selected. | ||

Check box | Select the check box of the job you want to delete. | ||

[Report] | This displays the screen for checking [Completed Job], [Out of range], or [Decording result]. | ||

[Error Report] | Displays the report list of an error that occurred during job execution. A report is output as a PDF file, and automatically deleted after the job was completed. This item is not displayed if no error occurs. | ||

[Back] | Returns to the previous screen without selecting an image. | ||

Remarks | The display of the streak, spot, [Barcode Area], or [Serial No. (0-9) Area] inspection result is an optional function. The inspection result is not displayed by default. To use this setting, please contact your service representative. | ||

Reference | - | ||

Screen access | Web Utilities - [List of Auto Image Inspection Report] | ||

Procedure

This displays the screen for checking [Completed Job], [Out of range], or [Decording result].

The report is displayed.

Display item | Description |

|---|---|

[Completed Job] | Report of printouts that satisfy the inspection level. A report of up to 1,000 pages can be created. A report is created in PDF format. If the number of pages exceeds 1,000, they are divided into different files, which are created as PDF files. |

[Out of range] | Report of printouts that do not satisfy the inspection level. A report is created in PDF format. The location of a problem is enclosed by a red frame, and the reason is displayed.  |

[Decording result] | Report of number or bar code decoding result. A report is created in CSV format. |

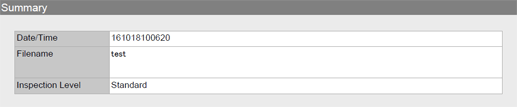

The inspection date/time and inspection level are displayed in the PDF file of a report. For details about each item, refer to the following.

-[Summary]

Type | Description |

|---|---|

[Date/Time] | Displays the date and time when an inspection was performed. |

[Filename] | Displays the file name used for printing. |

[Inspection Level] | Displays the inspection level. [Standard]: Standard [Essential]: Loose [Premium]: Stringent |

[Barcode check] | Displays whether bar code inspection was performed. |

[VDP Area Match(1st/2nd)] | Displays whether front/back matching of setting area was performed for bar code inspection. |

[Sequential] | Displays whether the sequential check was performed for bar code inspection. |

[Serial No.(0-9) check] | Displays whether serial No. (number) inspection was performed. |

[VDP Area Match(1st/2nd)] | Displays whether front/back matching of setting area was performed for serial No. (number) inspection. |

[Sequential] | Displays whether the sequential check was performed for serial No. (number) inspection. |

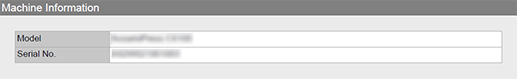

-[Machine Information]

Type | Description |

|---|---|

[Model] | Displays the name of the inspected model. |

[Serial No.] | Displays the serial number of the inspected model. |

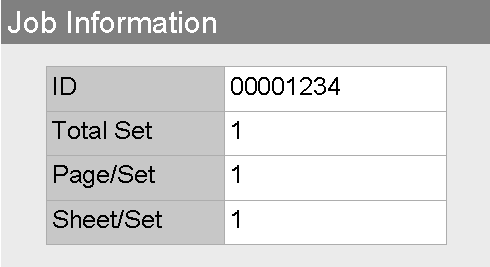

-[Job Information]

Type | Description |

|---|---|

[ID] | Displays the ID of the inspected job. |

[Total Set] | Displays the number of sets specified for a job. |

[Page/Set] | Displays the number of pages per set. |

[Sheet/Set] | Displays the number of sheets used per set. |

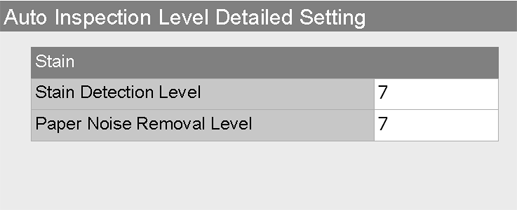

-[Auto Inspection Level Detailed Setting]

Displays the item specified in [Automatic Inspection Level Setting]. For details about [Automatic Inspection Level Setting], refer to [Automatic Inspection Level Setting].

Type | Description | |

|---|---|---|

[Stain] | [Stain Detection Level] | Displays the stain detection level. |

[Paper Noise Removal Level] | Displays the paper noise removal level. | |

[Spot] | [Detection Level(Highlight area)] | Displays the spot detection density level (highlight part). |

[Detection Level(Shadow area)] | Displays the spot detection density level (shadow part). | |

[Highlight Exclusion Level] | Displays the spot rear side permeation removal level. | |

[Thin] | Displays the spot rear side permeation removal level (thin paper). | |

[Spot Size Detection Level] | Displays the spot size level. | |

[Streak] | [Streak Detection Level] | Displays the streak stain detection density level. |

[Thin] | Displays the streak stain detection density level (thin paper). | |

[Highlight Exclusion Level] | Displays the streak stain rear side permeation removal level. | |

[Thin] | Displays the streak stain rear side permeation removal level (thin paper). | |

[Barcode] | [Barcode type] | Displays the type of bar code or QR code. |

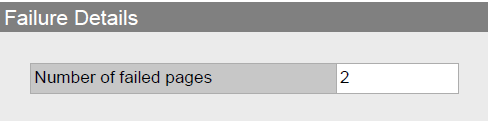

-[Failure Details]

The following items are displayed for a report in which an error is detected.

Type | Description |

|---|---|

[Number of Failed Pages] | Displays the number of pages that are judged to be outside the allowable range. |

[Number of Stain Detection Pages] | Displays the number of pages in which a stain is judged to be a non-standard image. |

[Number of Omission Detection Pages] | Displays the number of pages in which an omission is judged to be a non-standard image. |

[Number of Spot Detection Pages] | Displays the number of pages in which a spot is judged to be a non-standard image. |

[Number of Streak Detection Pages] | Displays the number of pages in which a streak is judged to be a non-standard image. |

[Number of Barcode Decode Error Pages] | Displays the number of pages in which a bar code / QR code reading or decoding error occurred. |

[Number of Barcode Blank Pages] | Displays the area in which the bar code or QR code was blank. |

[Number of Barcode 1st/2nd Mismatch Pages] | Displays the number of pages in which the front and back of a bar code or QR code did not match. |

[Number of Barcode Sequential Check Mismatch Pages] | Displays the number of pages in which the ascending order or descending order of a bar code or QR code did not match. |

[Number of Serial No.(0-9) Decode Error Pages] | Displays the number of pages in which a number reading or decoding error occurred. |

[Number of Serial No.(0-9) Blank Pages] | Displays the number of pages in which the number was blank. |

[Number of Serial No.(0-9) 1st/2nd Mismatch Pages] | Displays the number of pages in which the front and back of number did not match. |

[Number of Serial No.(0-9) Sequential Check Mismatch Pages] | Displays the number of pages in which the ascending order or descending order of a number did not match. |

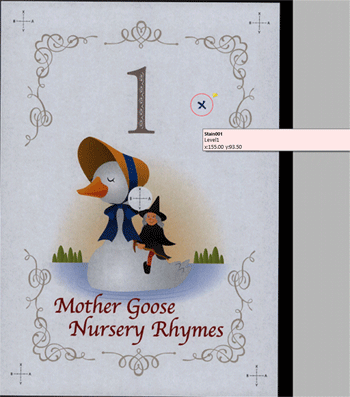

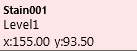

- Non-standard image

The location of a problem is enclosed by a red frame, and the reason is displayed as shown below. Also, the total number of problem locations is displayed in [Bookmarks] of a PDF file.

Type | Description |

|---|---|

[Stain(XXX)] | Displays the detected stain. XXX: Serial No. |

[Omission(XXX)] | Displays the detected omission. XXX: Serial No. |

[Spot(XXX)] | Displays the detected spot. XXX: Serial No. |

[StreakFD(XXX)] | Displays the detected streak in the paper feed direction. XXX: Serial No. |

[StreakCD(XXX)] | Displays the detected streak in the crosswise direction. XXX: Serial No. |

[Blank(m)] | Displays the area in which the bar code, QR code, or number was blank. m: Area No. |

[Decode Error(m)] | Displays the area in which bar code, QR code, or number decoding failed. m: Area No. |

[1st/2nd Mismatch(m)] | Displays the area in which front/back mismatching occurred in bar code, QR code, or number. m: Area No. |

[Sequential Check Mismatch(m)] | Displays the area in which a sequential error of bar code, QR code, or number occurred. m: Area No. |

[Level(X)] | Displays the spoilage detection level. XXX: Level |

[x:XXX.XX] [y:XXX.XX] | Displays the stain position based on the upper left of the image. x: Lateral position, y: Vertical position |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.